FAQ

-

Technical terms— what are rated functioning temperature (Tf), holding temperature(Th), maximum temperature limit(Tm) ?

Please refer to the explanation of technical terms. (terms explanation Link)

-

Can thermal cutoff (TCO) be used as current fuse?

No. TCO is only sensitive to temperature, so please use TCO strictly under its rated current and voltage.

-

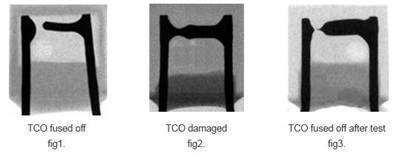

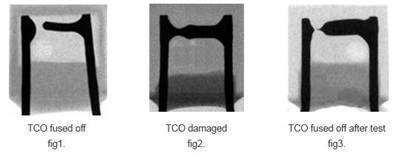

Why there is no conducting of TCO sometime after soldering? Why TCO is found open in testing after soldering or installing? How to avoid these kinds of situations?

This could be caused by the soldering temperature. During soldering process, the ambient temperature of TCO has reached the functioning point. As a result, TCO is vulnerable to fusing off or serious damage. Wrong behaviour are like soldering point too close to TCO body, soldering time too long, soldering temperature too high.

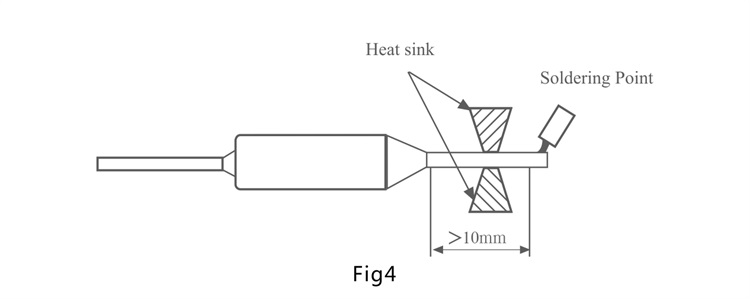

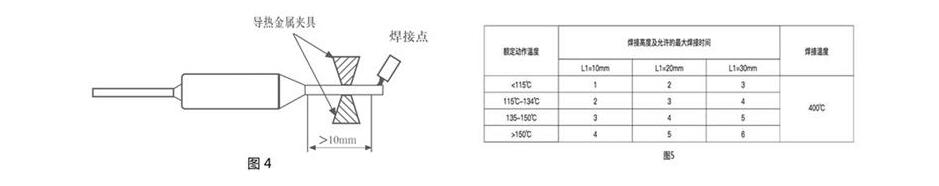

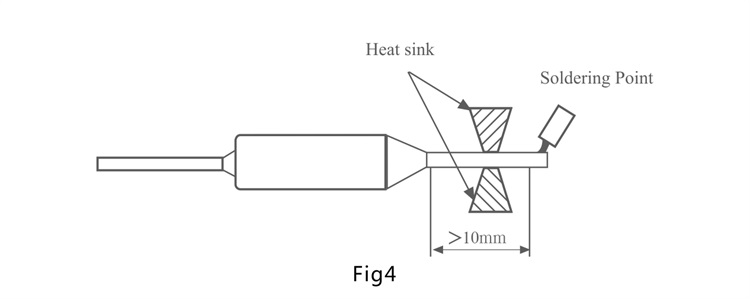

To reduce or avoid the damage to TCO, it is suggested that customers pay attention to the following tips:

1. Distance between the soldering point and TCO body should be at least 10mm. ( As showed in Figure4.)

2. Soldering time should be less than 3s.

3. Soldering fixture should be applied during manual soldering. Such as clipingan aluminum block (or other metals which are good at dissipating the heat) with the lead wires to help dissipate the heat.

4. Immerse the lead wires into the cooling liquid (like alcohol) after soldering.

-

When TCO is riveted, there is no heat source. How could TCO fuse off when the whole appliance is under testing?

This could be caused by the highvalue of contact resistancein the riveting position. When loading the current, the riveting position would generate heating due to high contact resistance and transfer to TCO. When the temperature rises to the rated Tf, it will function and cut off the circuit.

-

Can TCO bear tension or pressure? What is the parameter?

The case, epoxy and lead wires could not be pulled or pushed no matter when it is installed under the normal temperature or when it is used under environmental temperature. These actions could damage the internal sensing temperature part of TCO.

-

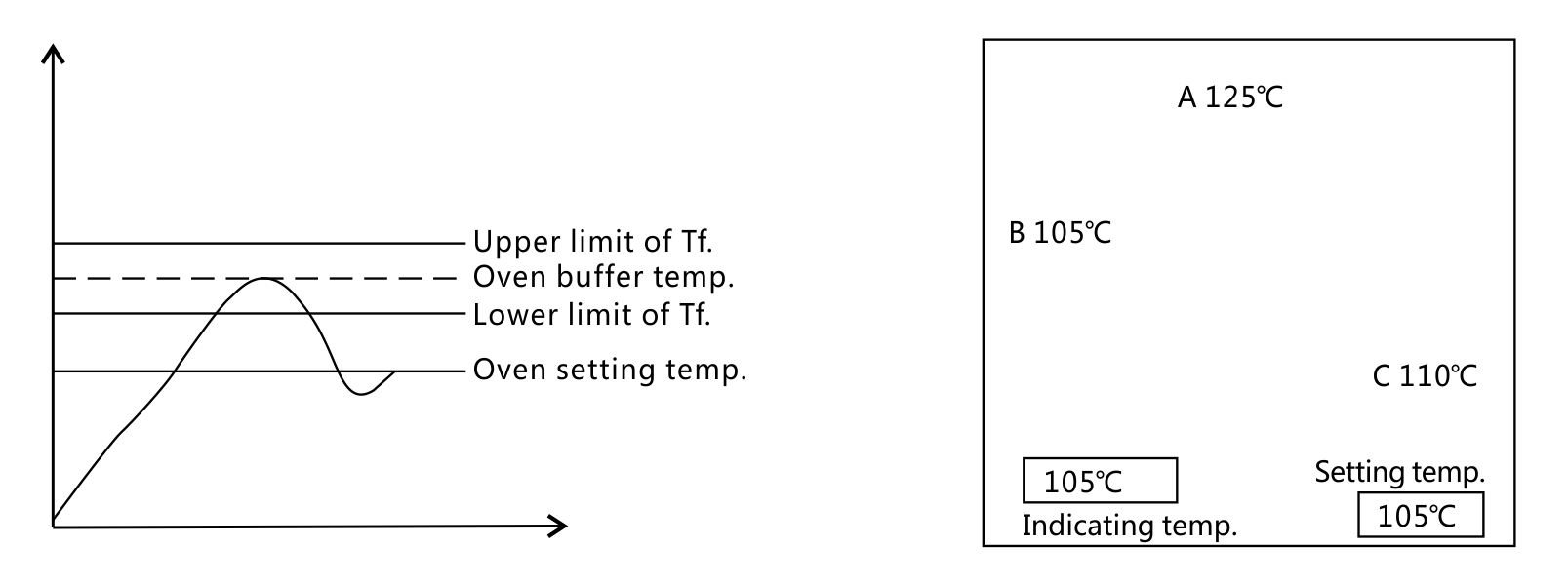

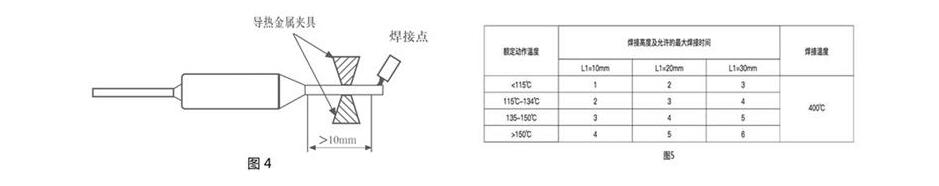

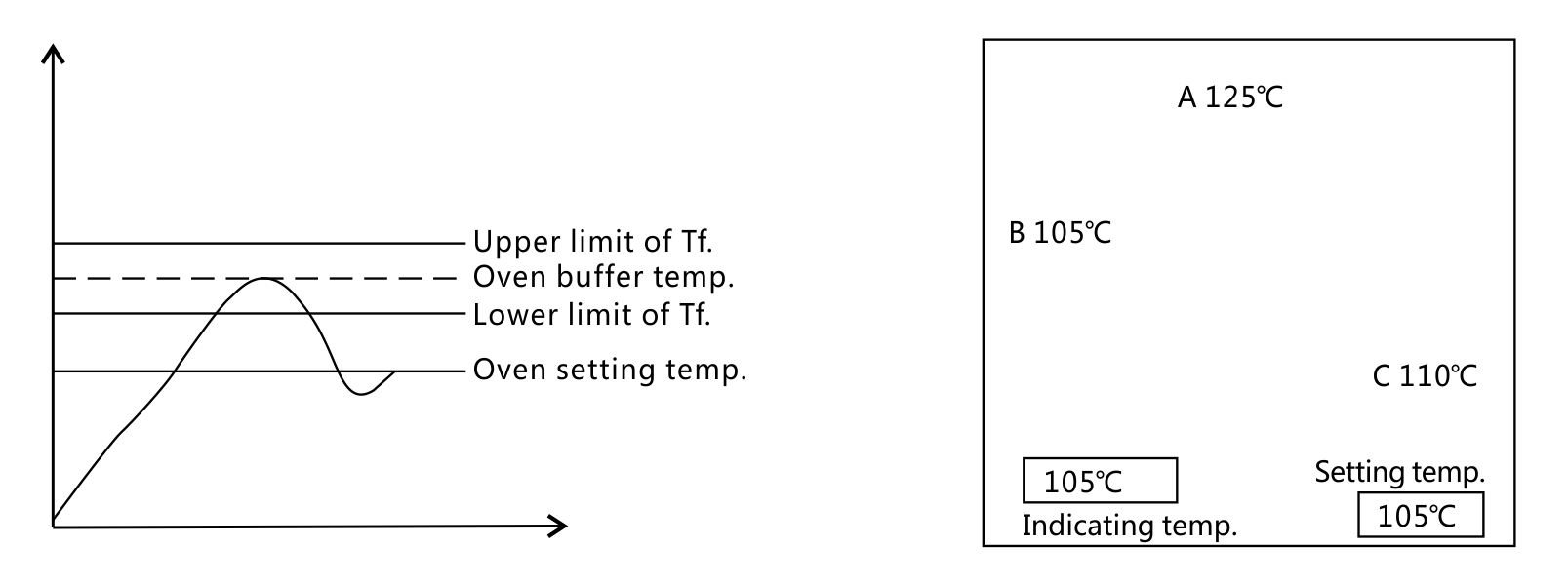

Why do TCO function in large volume when they are applied in the appliances and put in the oven for baking?

(1)The buffer temperature created by the heating process of the oven could be very high and cause TCO to function. (Refer to Fig.6)

(2)The temperature inside the oven is not uniform. Some positions are high, some are low. (Refer to Fig.7)

fig.6 fig.7

fig.6 fig.7(3)The air inlet and air outlet are blocked because of the amount is too much. Once holes of oven are blocked, the ventilation will be bad and temperature will get higher in part, which cause TCO to function.

-

Can TCO be put in the liquid or gas environments?

No. Considering the technique of TCO, it is not allowed to be used under environment of liquid, just as water or organic solutions, as well as the humid condition. It cannot be applied in the environment of corrosive gas (such as sulfur dioxide,hydroxide) either.

-

Why does TCO function during process of heat-shrinkable tubing? How to avoid this kind of situation?

During the process of heat-shrinkable tubing, the lead wires should feel the heat and transfer the heat to the thermal alloy. TCO functions when the temperature is high enough. Please pay attention that high temperature or long time of tubing may damage TCO or cause TCO to function.

In order to avoid the damage, it is proposed that customers check their technique of tubing. Please refer to the question “Why do TCO function in large volume when they are applied in the appliance and put in the oven for baking?”. If you are using air heater during the process, please guarantee the distance and time is reasonable to ensure the heat transferred to the TCO would not exceed its functioning temperature.

-

How to test the functioning temperature when conducting IQC inspection?

If you have a silicon oil bath for testing TCO’s functioning temperature. Please pay attention to below tips: 1. The current passing TCO is less than 10mA.2. Put the TCO into the silicon oil bath at a point of Tf-12℃.(For example, TCO of A4-F series should be put into the silicon oil bath when the temperature reach 118℃). You’d better keep the temperature constant for about 30 minutes.

4.The probe should be attached to the TCO as close as possible.

You could use a constant temperature oven with the blowing device to do the test if you don’t have a silicon oil bath. When using a constant temperature oven Please pay attention to:

a. Put the TCO into the silicon oil bath at a point of Tf-12℃. You’d better keep the temperature constant for about 30 minutes.

b. To ensure the accuracy of temperature inside of the oven, you’d better put the TCO into the oven together with a probe.

c. The temperature of silicon oil bath rise at a rate of 0.5-1℃ per minute till the TCO fuse-off.The rate of heating up can not exceed 1℃ per minute after putting in the TCO

-

How to install TCO to achieve the optimal performance?

There are two ways for TCO to sense the temperature.

1. The TCO body needs to be put close to the heat source. TCO feels the temperature through the body. As the body of TCO (alloy type)has no direct contact with the thermal alloy, it takes more time when the heat from the body transfer to the thermal alloy. The heat transfer rate is slow in the kind of installation. The fusing off action would come in with delay.

2. The lead wires of TCO need to be put close to the heat source or to be connected with the heat source directly. TCO feel the temperature through the lead wires. As the lead wires are connected to the thermal alloy directly, thermal alloy could feel the heat source once the lead wires feel it. Because the lead wires are no insulated, it is suggested that customers to put good heat transfer and good withstand voltage bushing outside of the them.PS: TCO is not allowed to be suspended inside of the equipment.

fig.6 fig.7

fig.6 fig.7